WMS Software

Supervise multiple warehouses, move inventory between them, and get reports to make more informed decisions with O2b Technologies ERP Solution. This is user-friendly, fast, and cost-effective.

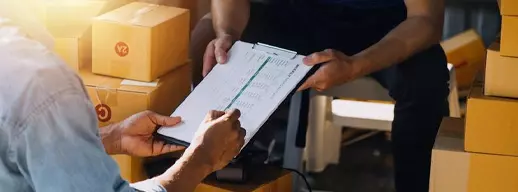

The warehouse management solution gives you full operational control over the storage and transportation of your products, delivering dependability to your control processes. The module is specifically designed for your warehouse's smart and effective management.

This WMS is an all-in-one warehouse management system for distribution, logistics, and warehousing businesses.

WMS Software manages several warehouses in several nations, transfers orders to streamline warehouse activities, and provides analytical data to determine your sales patterns and make wise business decisions.

The significant features and functionalities of the O2b Technologies integrated warehouse management system enable effective inventory management operations.

The warehouse manager can easily get all the detailed information about the warehouse operations like incoming orders, outgoing deliveries, activities running delays, and much more with the help of the warehouse dashboard. This platform displays the deep insights and live status of each activity and helps the concerned person and members to make quick decisions on each activity and assists them in taking quick action on the ignored activities. It also provides reminders and notifications for scheduled & non-scheduled activities.

The warehouse management system uses barcodes at every step of the process to reduce human error and deliver correct data instantly as it is capable of identifying the product at every stage, and location, and fetching other related details easily by providing real-time data. The code on a product is scanned using a barcode scanner. The warehouse management system reads the code and then starts tracking that particular barcode as the item moves throughout the warehouse.

WMS helps in managing the running operations between multiple locations of the warehouse with transparent communications among the teams. It supports the operational workflow of warehouses at various locations including inventory, staff, shipping, storage, spacing, delivery, receiving, and movement of goods. WMS helps you track all the activities of your warehouse at multiple locations using a single platform.

The RMA process states the return of any product due to issues like off-quality, defective, not as shown on the website, and others. In lieu of the return, some customers ask for replacements while others ask for a return with a refund. Few merchants accept the product returns as requested but, others accept only in selective conditions like defective, broken, etc. It plays an essential role in the reverse order fulfillment cycle. It makes it possible for your business to manage returns and exchanges in a way that cuts down on extra work and lowers operational costs.

WMS offers a full inventory tracing and tracking system that enables users to conduct complete, reasonable physical audits. The physical audit must be carried out using handheld scanning machines, barcode labels, and inventory objects with barcodes. It involves documenting and keeping track of a product's movement from the time it enters your warehouse to the time it leaves at shipment, as well as keeping track of those records for a certain amount of time after the product has left your hands in case of a future recall.

WMS saves the pickers’ time in picking the batch of orders from the same location when receiving the orders in the warehouse. When done properly, this increases productivity and gives pickers clearer pathways across the warehouse so they don't have to go back and forth along the aisles to collect goods later. Orders that require the same SKU are grouped into a single set, reducing the number of times the location is visited by the picker once rather than every time for every single order. Hence, the ultimate goal is to avoid revisiting the same location.

WMS helps its users to assign the serial/ lot numbers to the products. Moreover, it further supports tracking the stocks’ transactional history in detail for accurate traceability. It includes 4 types of traceabilities:

It is required to adjust inventory levels to respond to changes in the real inventory count that might not be reflected in your records. Inventory adjustments are performed to correct the differences between recorded and real inventory items. Adjustment may include positives due to the result of production adding additional inventory, or excess inventory that is still usable but did not sell. However, negative inventory adjustments are because of waste, breakage, theft-related losses, write-offs, internal use, and other reasons.

The accounting process of giving a company's inventory a value is called inventory valuation. There are several ways to determine inventory value. For example, the First In, First Out (FIFO) method values inventory as if the first inventory items bought are the first to be sold; the Last In, First Out (LIFO) method values inventory as if the costs of the most recent products bought or produced are the first to be expensed; and the Weighted Average Cost (WAC) method bases its calculations on the average cost of the items bought.

These are the guideline of a set of rules that assist the warehouse manager in creating certain rules to fill their warehouse with stocked goods. Under this, users set up the minimum-maximum inventory level, when any stock goes below the set minimum stock level it automatically raises a PO to the purchasing department so that they can get a timely alert for the procurement of that particular inventory. And, hence saves the inventory from getting out-of-stock or unavailable at the receiving of any new order.

WMS enables its users to choose the best routing option for their warehouse operations including

The user can do the overall product management operations with the support of WMS. WMS shares detailed insights into the product categories, product types, and product variants with UoM(units of measure). The inventory items are measured and monitored using UOM. It is a physical unit that we use to measure and control various items, similar to kilograms, dozen, meters, etc. It is possible to use various UOMs for various operations.

By taking previous sales data, analysis, and other available records, the WMS helps in forecasting the inventory for future customers that can be needed to meet their orders. Using warehouse forecasting, you can determine how much inventory you'll need and when and where you need for order fulfillment. So it's a great method to estimate how much inventory you'll need to send to those exact locations at those specific times. This safeguards the businessman from getting out of stock or over-stocking the inventory.

Find out everything about the inventory module's financial operations. Easily track and monitor all in-flows & out-flows of stocks and their respective bills and invoices.

For the purposes of all like manufacturing, distribution, e-commerce sales, and more. the connection of the sale module with the inventory module would be beneficial.

The purchase module integration will help to manage the product procurement processes, which may be automated by specifying certain inventory module features.

WMS is already integrated with various shipping connectors such as UPS, USPS, XPO, FedEx, Stamps, and many more.

We have a huge base of satisfied customers and they are accomplishing their business objectives more quickly.

Boost your sales and effectively complete orders with the help of our advanced warehouse management and order management services.

Chat Now

Get live help and chat with WMS expert.